- 1st January 2026

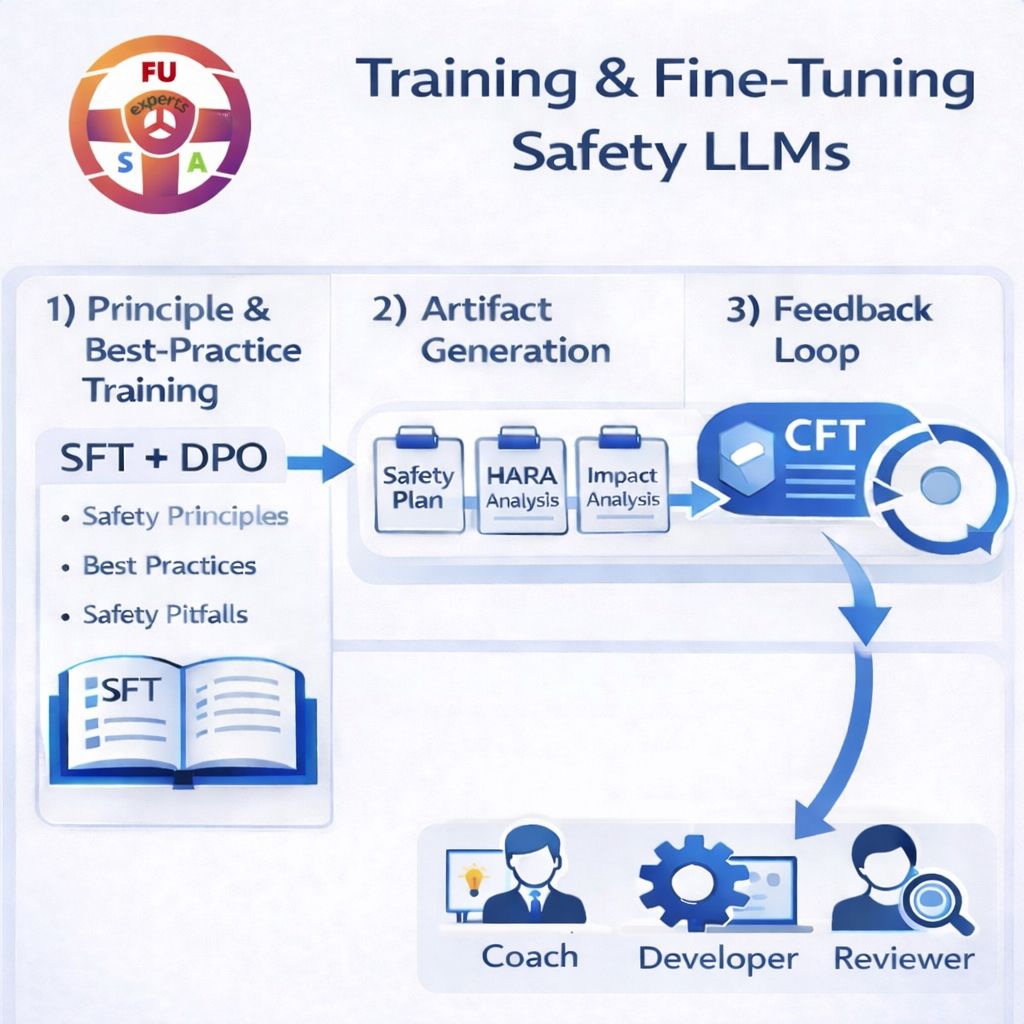

FuSaExperts is training and fine-tuning LLMs specifically for safety engineering—because general-purpose LLMs are not reliable enough for standards-driven work. In functional safety, it’s not about sounding correct; you need consistent application of safety principles, best practices, and repeatable, review-ready outputs across artifacts like Safety Plan, HARA/risk analysis, FSC/TSC, impact analysis, and change management.

Our approach uses fine-tuning methods that match the role and the work package:

SFT (Supervised Fine-Tuning) to teach correct structure, terminology, and expected outputs (templates, content patterns, lifecycle logic).

DPO (Direct Preference Optimization) to align the model with safety-quality preferences (clarity, traceability, conservative assumptions, and fewer hallucinations).

CFT (Critique Fine-Tuning) to harden performance through targeted critiques and revisions—especially important for reviewer behavior and for reducing recurring failure modes.

We apply these methods differently depending on whether the model acts as a Coach, Developer, or Reviewer, and depending on the exact safety task (e.g., safety planning vs. risk analysis vs. impact analysis vs. safety concept).

Our fine-tuning workflow is structured in three phases:

Principles & best-practice training: SFT + DPO to internalize safety engineering principles, accepted best practices, and typical pitfalls seen in audits and assessments.

Artifact production: the model generates real safety work products (structured, traceable, auditable).

Feedback loop: we use CFT on real outputs and review findings to continuously improve quality, consistency, and reviewer readiness.

- 22nd December 2025

We’re introducing a new training: Safe AI — a hands-on program that covers the relevant norms and standards, current and upcoming trends in robust LLMs, the AI safety life-cycle, AI architecture from a safety perspective, safety analysis methods, and safety argumentation; every topic is backed by demonstrations, real-life examples, and concrete case studies so teams can translate the concepts directly into engineering practice.

For more information click here

- 08th November 2025

Call for cooperation / New position open

- 31st July 2025

The development of our AI-based Safety Advisor continues to advance, driven by real-world use-cases across the safety lifecycle — including safety management, impact analysis, and safety analysis. We implemented a Retrieval-Augmented Generation (RAG) framework based on existing safety artifacts, combined with task-specific LLM selection to maximize reasoning accuracy and consistency. To handle structural dependencies across work packages, we introduced LongGraph as a backbone for safety logic flow, supported by a vector database enabling semantic retrieval within context. This setup has already led to measurable improvements, such as the identification of critical change impacts and increased consistency in artifact alignment. In parallel, we are actively strengthening the platform’s robustness through architectural and validation measures to ensure traceable and audit-ready results in compliance-critical environments.

- 24th April 2025

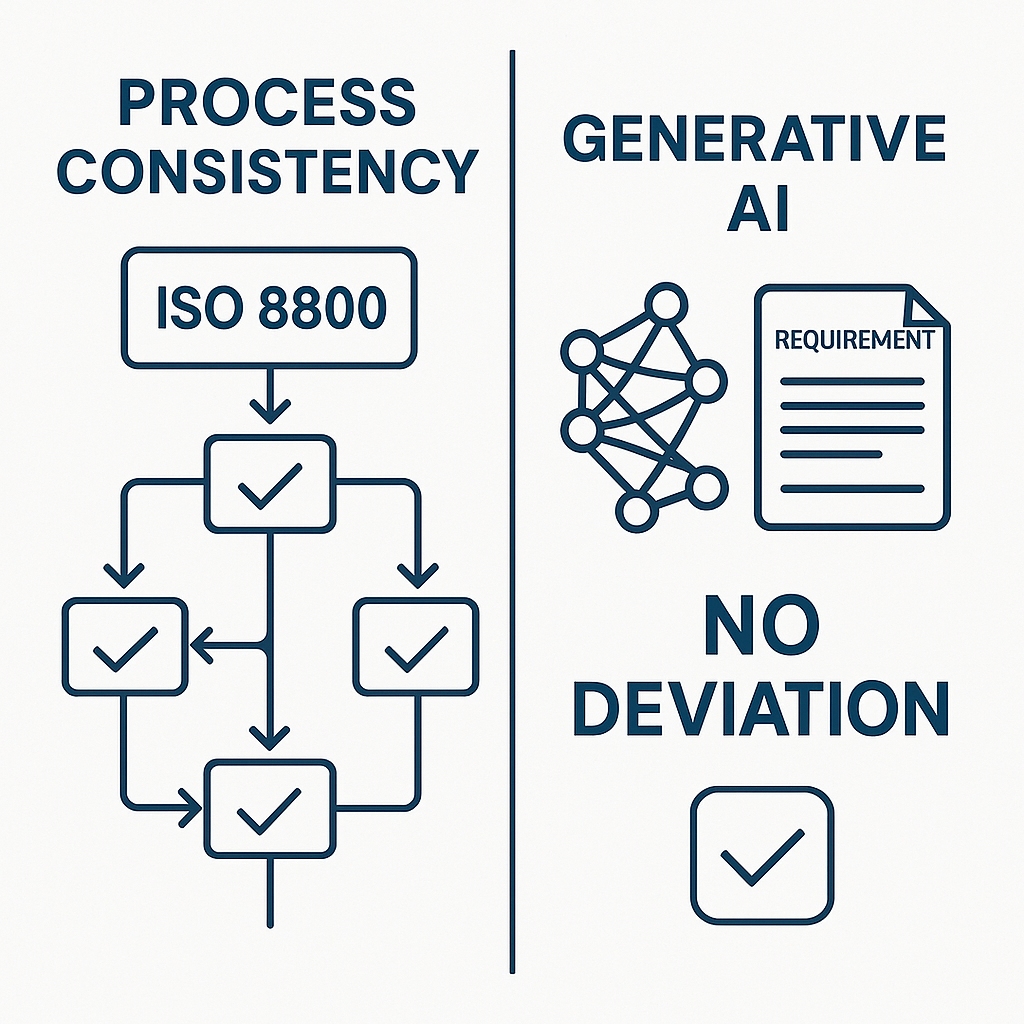

FuSaExperts invites partners to collaborate on advancing AI in safety-critical systems, focusing on two distinct directions:

- Process-Driven AI Integration

Aligned with standards such as ISO 8800, the company ensures AI integration through strict process consistency, prioritizing safety and reliability in compliance with recognized norms. - Generative AI for Development and Safety Justification

Leveraging customized LLMs, FuSaExperts supports the development and safety justification of critical systems, ensuring zero deviation from specified requirements for full compliance.

- 27th January 2025

We are excited to announce the launch of our new training program, “Functional Safety for Managers”, designed to empower leaders with the knowledge and skills to effectively integrate functional safety into their management practices. This comprehensive training is tailored to meet the unique challenges managers face in safety-critical industries.

Training Highlights:

- Understanding Safety Culture:

- Importance of fostering a safety-first mindset across the organization.

- Strategies to embed safety culture into daily operations.

- Integrating Safety and Quality:

- The synergy between safety and quality for achieving operational excellence.

- How to balance compliance with efficiency.

- Workflow Design and Effort Estimation:

- Building workflows that align with functional safety requirements.

- Techniques for accurate effort estimation in safety-related tasks.

- Defining Roles and Responsibilities:

- Clear delegation of safety-related roles within teams.

- Ensuring accountability and collaboration for effective implementation.

- Safety Assessment:

- Principles of functional safety assessment and key deliverables.

- Preparation for audits and continuous improvement cycles.

Interactive Case Study:

- Safety Planning in Action:

- Hands-on exploration of a real-world scenario.

- Developing and executing a functional safety plan from initial concept to review stages.

- Identifying common pitfalls and implementing solutions.

This training is ideal for managers who oversee safety-critical projects or are involved in decision-making processes related to safety and quality. With this course, participants will gain actionable insights and practical tools to elevate their leadership in functional safety.

For more information or to register, contact us today!

12 December 2025

Safety Tool Chains. This event will bring together industry leaders, experts, and innovators to explore strategies for optimizing workflows, enhancing safety protocols, and integrating advanced tools to drive progress across the field.

Event Details:

- Topic: Engineering and Safety Tool Chains: Challenges, Innovations, and Future Directions

- Date: 20th December 2024

- Time: 09:00 a.m. PST

- Location: on-line

Agenda:

- Current Landscape: An overview of engineering tool chains and safety standards.

- Challenges & Opportunities: Identifying gaps and potential improvements in current practices.

- Innovation Showcase: Presentations on emerging technologies and solutions.

- Collaborative Exchange: Open forum for discussions, ideas, and networking.

- Strategic Outcomes: Actionable steps for future advancements.

Who Should Attend?

This event is designed for professionals, decision-makers, and stakeholders in engineering, safety, and related industries. Whether you’re looking to share your expertise, gain insights, or collaborate on pioneering solutions, this discussion offers a unique opportunity to connect with like-minded individuals.

Please register by 12th of November 2024 by e-mail to secure your place

We look forward to welcoming you to this collaborative event and working together to shape the future of engineering and safety tool chains.